时间:2020-01-22 15:58:17 浏览量:48

Overview of connectors

With the development of science and technology, communications, aerospace and military industry have gradually played a very important role in modern science and technology. The connector pins and sockets play an important role in transmitting signals in the above fields, and they often need to be plated with gold. The purpose of gold plating is to improve the oxidation resistance, corrosion resistance and conductivity of products. Due to the particularity of the industry, it has strict requirements on the thickness of gold plating, welding performance, gold plating depth in blind holes and corrosion resistance of parts.

Industry status

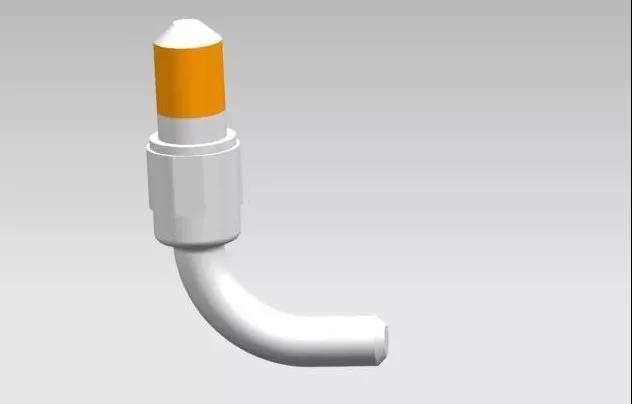

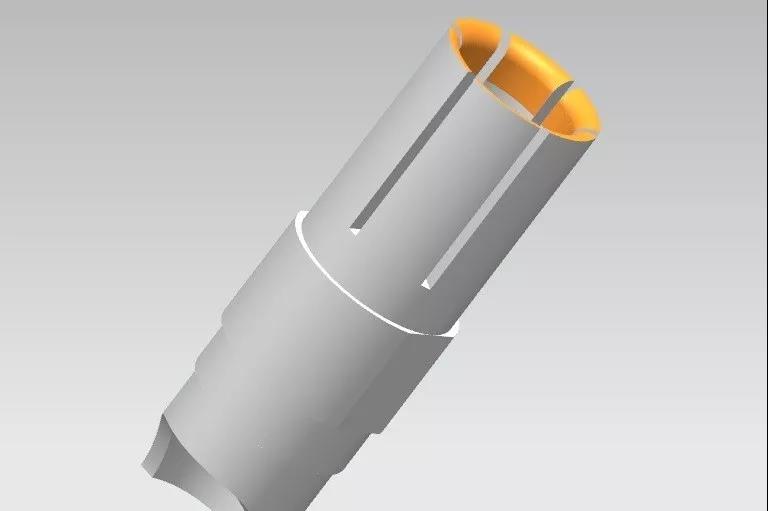

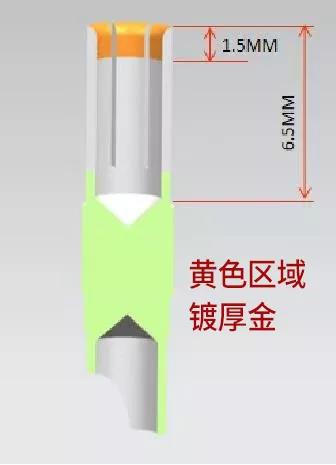

As long as the contact part (i.e. functional area) of connector pin jack is plated with gold (Au ≥ 1.27 μ m) Other areas are plated with thin gold (Au ≤ 0.3 μ m) Can meet the requirements (see the figure below). Unfortunately, there are still some defects in the local gold plating technology of connector pins and sockets in the industry. In particular, the local gold plating technology in connector sockets is even more insufficient, and the sockets are often all plated with thick gold. In addition, the problem of blind hole depth gilding technology is also long-standing. The parts that should be gilded cannot completely cover the gold.

The connector pin jack is plated with thick gold outside the functional area, which has certain disadvantages. 1. When it is used in the aerospace and military fields, it requires highly reliable welding products. When the gold content in the welding position exceeds a certain proportion, the phenomenon of "gold brittleness" will occur, affecting the welding performance. 2. The extra gilded part will undoubtedly increase the cost and bring cost pressure to the customer, especially the cost pressure of civilian products.

For the micro jack of the blind hole type in the connector, in order to ensure its good signal transmission capability, all holes are required to be gold-plated. If the hole is not completely covered with gold, the contact resistance of the contact surface is large when it is combined with the contact pin, resulting in poor signal transmission and affecting the normal operation and safety of the equipment.

Hard work creates good reputation

After years of research, Aidisheng Plating has finally developed the precise gold plating technology for the functional area of connector jack and the deep gold plating technology for blind holes.

The precise gold plating technology for the functional area of the connector socket can be used to partially gild the functional area in the connector socket according to the customer's requirements, which not only ensures the electrical conductivity, corrosion resistance, welding and other performance requirements of the connector pin socket, but also saves gold, or even reduces the cost by more than 60-70%. For example, the depth of the jack is 6.5mm. The customer requires that only the 1.5mm functional area near the hole be gilded. Edison Plating can precisely gild the designated functional area.

Blind hole deep gold plating has also been a difficult problem puzzling the electroplating industry. Various scientific research institutions and enterprises have invested a lot of energy in research. With the miniaturization of connectors, the jack hole diameter is smaller, the electroplating in the hole is more difficult, and the requirements for deep hole electroplating technology are higher. After nearly ten years of continuous experimental improvement, Aidisheng has developed a set of blind hole gold plating technology, especially the hole diameter is less than 0.3mm, The blind hole parts with hole depth more than 5 times of the hole diameter are gold-plated. This industry-leading technology has solved practical problems for many users.

The rise of China's manufacturing industry requires a large number of enterprising Chinese enterprises to strive for it! Aidisheng electroplating will surely become the preferred supplier of global functional electroplating (gold silver tin)!