-

Company Profile

-

Recruit

Aidisheng provides customers and industrial partners with complete electroplating solutions for new energy vehicle connectors

Introduction to relevant electroplating

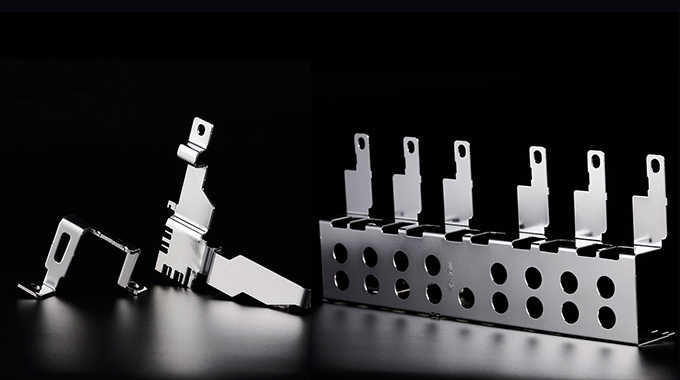

At present, such products are mainly involved in electroplating processing, such as sensor components, high current terminals, power exchange connector terminals, new energy charging posts or guns, relay terminals, three electricity connection bar components, etc. Generally, gold plating, silver plating, tin plating, nickel plating or chemical nickel plating can be selected, and continuous plating, barrel plating, hanging plating, local plating and other electroplating methods can be used.

Among them, hard silver electroplating is widely used in new energy vehicle connectors. Compared with ordinary silver, hard silver has excellent friction resistance, which can improve its service life in connector type products. The Vickers hardness can reach 160-180HV, and the hardness is still greater than 140HV after thermal attenuation (150 ℃, 200h). The coating thickness can reach 1-200 microns.

Application

Application

Application

Application

Application

Application

Application

Application